The Antique Gas & Steam Engine Museum

by Jason Crawford · April 21, 2019 · 2 min read

Last weekend I went to the Antique Gas & Steam Engine Museum in Vista, CA. I’d been wanting to go there ever since I was researching textiles and looking for a way to see old looms in action (yes, they have looms in addition to engines and other exhibits). I happened to be in the area and stopped by.

Unfortunately we came on a Sunday when many of the exhibits are closed, but the blacksmith’s shop was open, so we got to see some machine tools, and there are plenty of tractors and engines viewable every day of the week.

This is a planer, a machine tool for making flat (plane) surfaces. It has a little sort of tooth on it; you adjust it to the right height and then you move the piece you’re working underneath it to kind of scrape a surface:

The tooth (head? bit? not sure what to call it) would get hot as you worked—possibly hot enough to get soft or deform. The solution, around the turn of the last century, was an alloy of steel with tungsten called “high-speed steel” that could withstand much higher temperatures.

This I think was a milling machine:

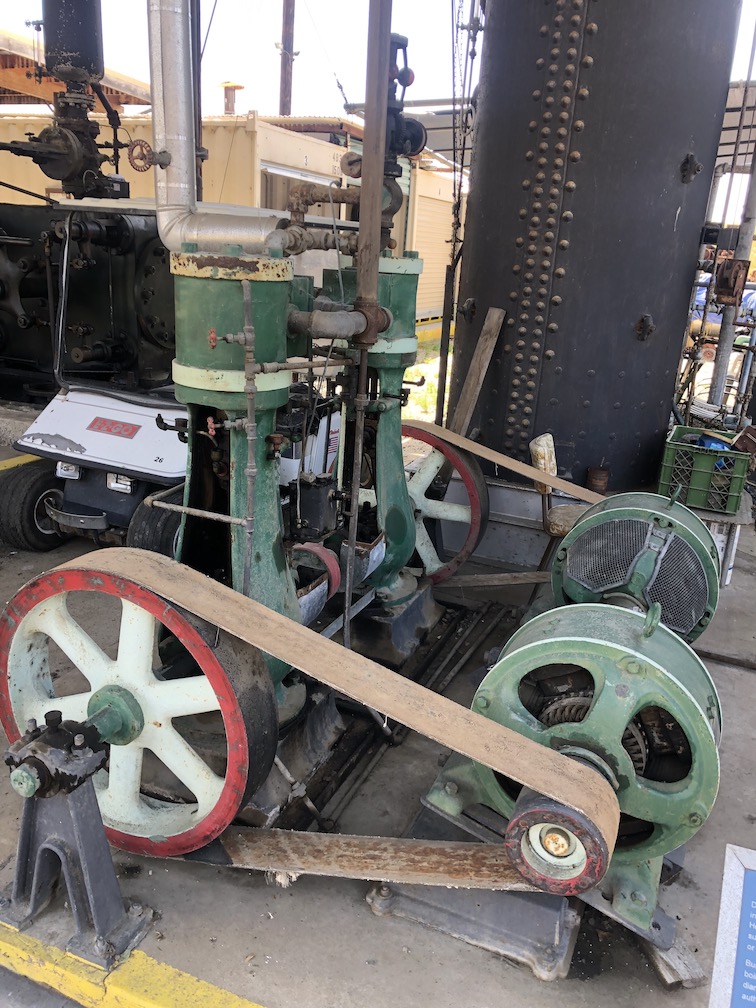

The machine shop was powered by a single, large engine (not pictured) that could run on either gasoline or kerosene. It drove a central shaft in the ceiling that ran the whole length of the shop. Individual machines were hooked up to the shaft with belts:

Note the two twists in the belt. The belt is twisted in a figure-eight for a simple reason: to reverse the direction of the rotational motion. But if you look closely, you will see that it is also given a half-twist to turn it into a Möbius strip! This arrangement means that both sides of the belt come into contact with the wheels, which spreads the wear out evenly and is supposed to make it last twice as long.

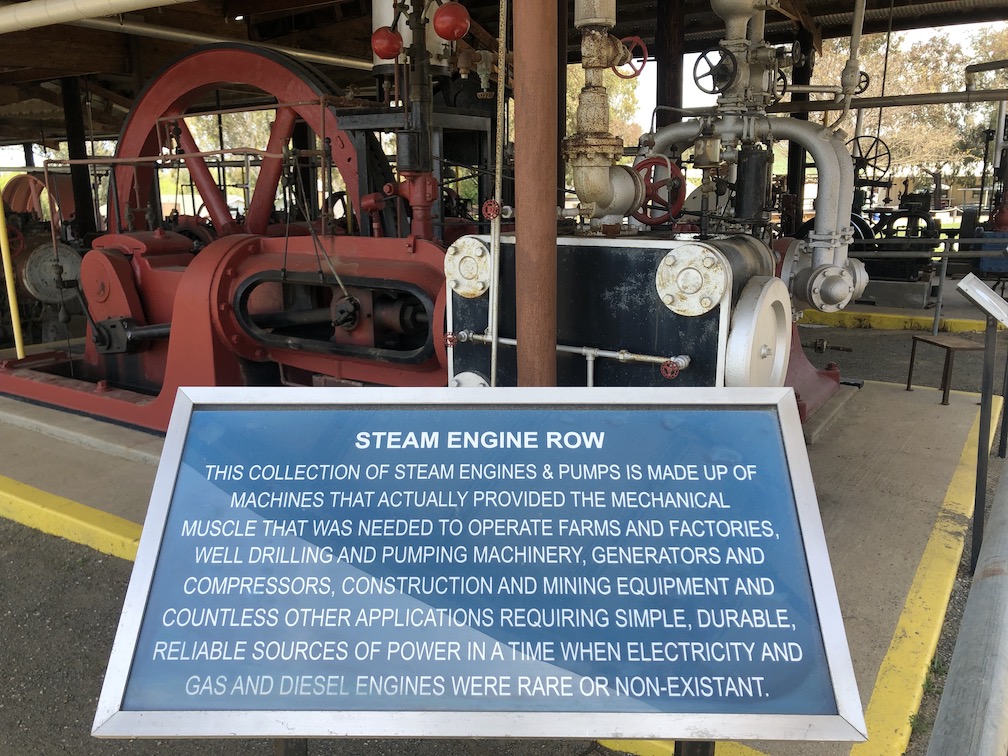

Next we wandered over to Steam Engine Row:

One of the larger steam engines (the long hole in the piston must be a cutaway so you can see the insides):

The funny balls on the top are a regulating mechanism. The faster the machine turns, the higher the balls rise, owing to centripetal force. As the balls rise, though, they gradually close off a valve, which slows the machine down. As the machine slows, they fall, opening the valve. This creates a negative feedback cycle that keeps the machine at the desired speed:

Some of the engines were early electric generators, with the belt hooked up to an electromagnet:

Here’s an even larger electromagnet:

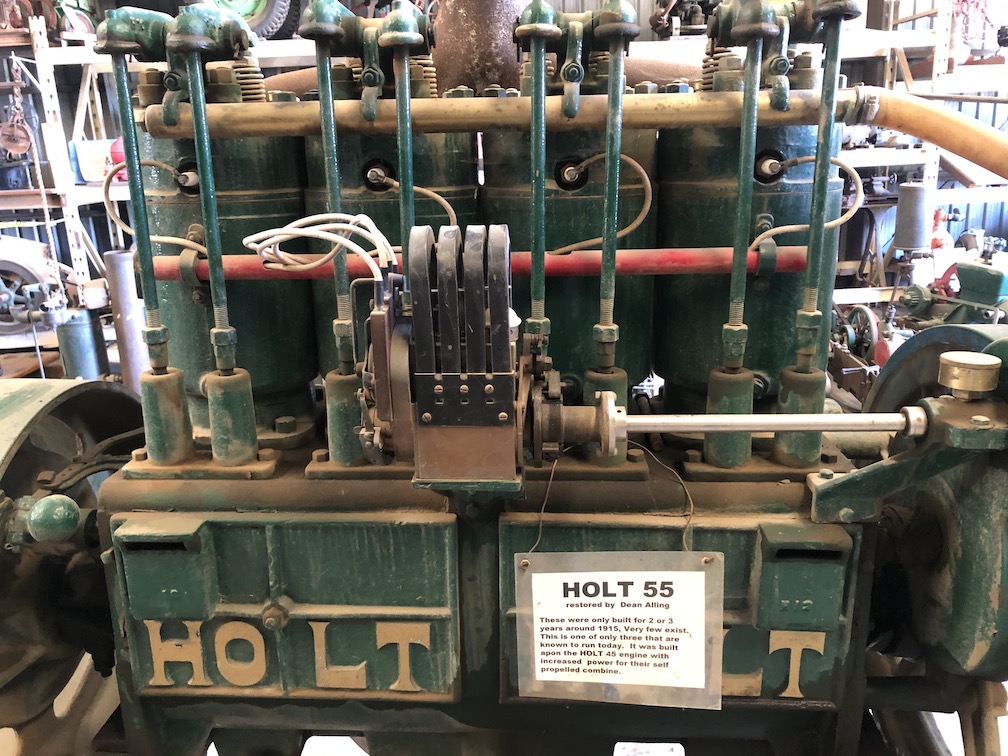

There were also a bunch of tractors and similar machines I took pictures of just because I thought they were interesting:

Update, Dec 2019: Redditor rmm4pi8 informs me that this is a “hit-and-miss engine”, a common stationary engine in the early 1900s.

I’ll have to go back in the fall for their Antique Engine & Tractor Show. Then the Palomar Weaver’s Guild should be open and I can finally see the looms!

Coming soon, a post on the history of steel. I’ve already read a book on the subject, a couple of articles, and several Wikipedia entries; but I’m still a bit fuzzy on too many things, so I’m researching more before I finish the draft.